History of membrane keyboards is a concise journey for readers of Keyboards Technology. I define a membrane keyboard in plain terms, explain the basic idea of layered membranes and conductive traces, trace early roots in calculators and appliances, map the timeline to mass adoption in consumer gear and laptops, and compare core builds (full membrane, rubber dome over membrane, and scissor-switch hybrids).

I weigh the pros — low cost, thin profile, quiet keys, and spill resistance — against the limits like weaker tactile feedback and wear, and I touch on manufacturing advances, conductive inks, sustainability, and future trends so you get a compact, clear view.

Key takeaway

- Membrane keyboards use thin layered films and printed conductive traces to register keys.

- They began as low‑cost input pads and became common in laptops, remotes, and calculators.

- Strengths: affordable, slim, quiet, and often spill‑resistant.

- Limits: milder tactile feedback, potential wear under heavy use, and less multi‑key precision than mechanicals.

- Recent trends: better tactile domes, hybrids, improved materials (PET, silicone), and greener manufacturing.

What is a membrane keyboard?

A membrane keyboard is a keyboard built from flexible sheets instead of individual mechanical switches. One layer carries printed conductive traces; a spacer keeps the top and bottom traces apart until a press brings them into contact, closing the circuit and sending a key signal.

My first use of one in the 1990s—soft and quiet—helps explain why this design stayed popular: simple, cheap, and compact.

Basic principle: layered membranes and conductive traces

The stack is straightforward:

| Layer | What it is | Role |

|---|---|---|

| Top layer | Thin plastic or film with printed key labels | Guides press and carries upper traces |

| Spacer (middle) | Sheet with holes at key positions | Keeps traces apart until pressed |

| Bottom layer | Film (often PET) with printed traces | Holds lower traces and completes the circuit |

| Backing | Stiff base or frame | Supports the stack and protects parts |

Think of the layers like pages in a book: only when you press a page at one spot do the words meet.

Key components to note: conductive traces (carbon or silver-based conductive ink) and the contact point where traces touch.

Common uses and why it matters

Membrane keyboards appear in:

- Office keyboards (budget models) — low cost, quiet

- Laptops and slim keyboards — space-saving

- Remote controls, calculators, POS pads — compact and cheap

- Industrial panels, medical devices — easy to seal and clean

If you build or buy keyboards, knowing these strengths helps match technology to the task. For hobbyists, membrane boards are quick, low-cost prototypes.

Origins and early innovations

Studying the history of membrane keyboards shows how printed films and simple mechanics displaced heavier switches.

- Early membrane-like switches appeared in calculators and appliances (1970s): printed conductive traces on flexible films reduced cost and thickness.

- Improvements in elastomers, adhesives, and printing through the late 1970s–1980s improved feel and lifespan.

- Integration with sealed fronts brought spill resistance and broader consumer adoption.

Key prototype milestones:

- Printed circuit overlays on flexible films

- Spacer sheets to keep contacts open until pressed

- Elastomeric domes for tactile feedback

- Silicone rubber tops for longevity and feel

- Sealed front panels for washability and protection

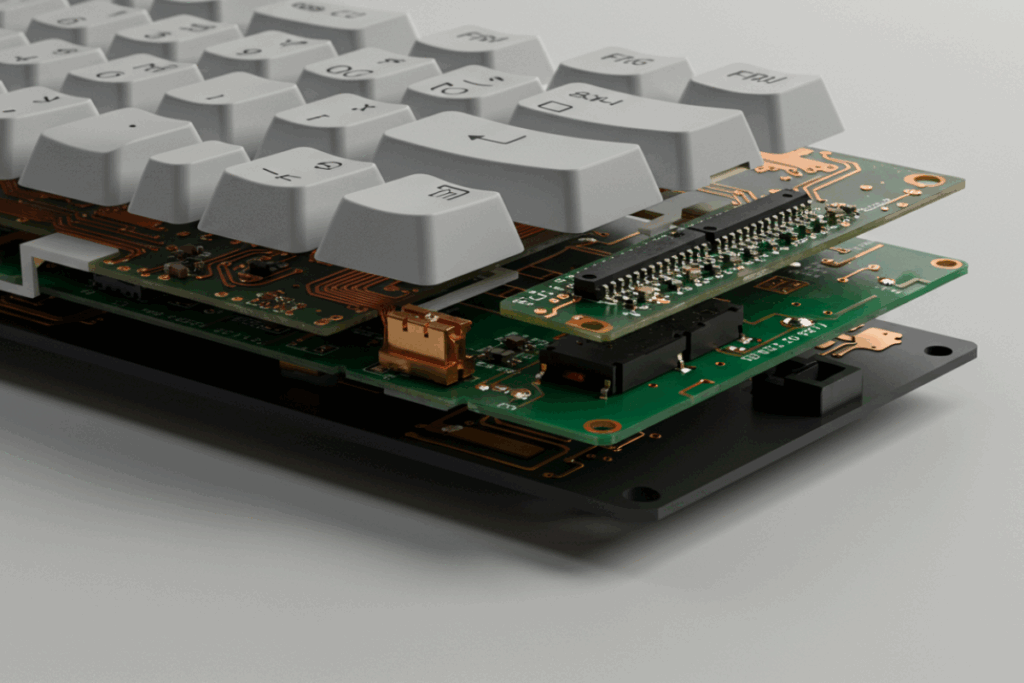

Core construction and variants

Three‑layer membrane design and materials

A typical membrane keyboard uses three layers: top film (labels), spacer, and bottom film (circuit). Common materials:

- PET (polyethylene terephthalate) — durable film for printed circuits

- Silicone — used for domes or tactile parts (soft return)

- Conductive ink — carbon or silver-based ink printed on film

When you press, the top layer bends through the spacer’s hole and contacts the bottom trace, closing the circuit.

Main variants

- Rubber‑dome over membrane: Rubber domes over membrane layers; common in budget office keyboards — soft with a noticeable pop.

- Full membrane: No separate dome; single flexible layers; very thin and flat (remotes, slim devices).

- Scissor‑switch hybrids: Scissor stabilizer over a membrane contact; short travel and firmer feel (laptops).

| Type | Construction | Feel | Common use |

|---|---|---|---|

| Rubber‑dome over membrane | Rubber domes on membrane | Soft, tactile pop | Office keyboards, budget models |

| Full membrane | Single flexible layers | Very soft, flat | Remotes, slim gadgets |

| Scissor‑switch hybrid | Scissor stabilizer membrane contact | Short travel, crisper | Laptops, low‑profile boards |

Conductive inks & manufacturing

Conductive ink (carbon or silver) printed on PET film makes flat circuits without wires. Manufacturing steps: roll‑to‑roll printing, cutting films, automated dome stamping or scissor assembly, and final sealing. That automation keeps costs down and quality consistent.

Sustainability trends: recyclable films, reduced adhesives, safer inks, and waste reduction in roll‑to‑roll processes.

Market adoption and impact

Membrane keyboards quietly powered many consumer and industrial products:

| Decade | Device | Main benefit |

|---|---|---|

| 1970s | Calculators | Low cost, mass education use |

| 1980s | Remote controls | Lightweight, low production cost |

| 1980s–90s | Telephones & low‑end PCs | Sleeker designs, cost savings |

| 1990s–2000s | Laptops | Thinness, lighter weight |

Why membrane keys mattered for compact devices:

- Take up less space than mechanical switches

- Weigh far less, aiding battery life

- Lower manufacturing cost per unit

Market roles:

| Market | Why membrane wins | Examples |

|---|---|---|

| Consumer | Price and slim design | Remotes, toys, budget laptops |

| Industrial | Sealing and cleanability | Control panels, medical devices |

Advantages and limitations

Advantages

- Low cost — affordable to produce and replace

- Slim profile — enables thin devices

- Quiet operation — suitable for shared spaces

- Spill resistance — sealed designs withstand spills/dust

Limitations

- Less tactile feedback — mushier feel vs mechanical switches

- Durability concerns — heavy use can reduce responsiveness over time

- Typing ergonomics — flat, low travel can be fatiguing for long sessions

These trade‑offs explain why heavy typists often prefer mechanical switches, while designers choose membranes for size, silence, and cost.

Membrane vs mechanical — a brief comparison

| Topic | Membrane keyboards | Mechanical keyboards |

|---|---|---|

| Early use | Affordable home/office devices | Offices, then gaming/typing pros |

| Feel | Soft, less tactile | Clicky or tactile, stronger feedback |

| Cost | Lower | Higher (individual switches) |

| Durability | Good for light use | Often longer life under heavy typing |

| Noise | Quiet | Can be loud (varies) |

| Typical buyers | Budget users, offices | Gamers, writers, heavy typists |

Improvements and future trends in the history of membrane keyboards

Tracking the history of membrane keyboards, the tech evolved from flat pads to better dome designs and hybrids that approach mechanical feel.

Trends to watch:

- Improved tactile domes with tailored actuation curves

- Thinner, tougher materials (silicone‑polymer blends)

- Hybrids that mix membrane and mechanical traits

- New conductive inks for finer traces and printed electronics

- Greater focus on recyclability and modular repairability

- Integration with sensors for backlighting or gesture controls

These changes keep membrane designs relevant for cost‑sensitive and space‑constrained products.

Timeline highlights

| Era | Key shift | Impact |

|---|---|---|

| 1970s–1980s | Early membrane pads in calculators | Low cost & simple design |

| 1990s | Rubber‑dome mass production | Cheap, quiet, widely adopted |

| 2000s | Improved domes & polymers | Longer life, better feel |

| 2010s | Low‑profile & hybrids | Slim boards, improved typing |

| 2020s | Sustainability & printed electronics | Less waste, new form factors |

Conclusion

The history of membrane keyboards is the story of simple layers enabling thinner, quieter, and cheaper input devices. They remain indispensable where size, noise, cost, or sealing matter most.

While not the choice for every heavy typist, modern advances in tactile domes, materials, and hybrid designs continue to narrow the gap with mechanical switches. With better conductive inks and greener manufacturing, membrane technology will keep evolving and serving countless devices.

Frequently asked questions

Q: What is the history of membrane keyboards?

A: The history of membrane keyboards traces back to the 1970s–80s when printed conductive traces on flexible films powered calculators and remotes. Improvements in materials and domes led to mass adoption in consumer and portable electronics.

Q: How did membrane keyboards evolve over time?

A: They evolved from simple flat sheets to rubber‑dome overlays, then to scissor hybrids and refined tactile domes. Manufacturing moved to roll‑to‑roll printing and automated assembly.

Q: When did membrane keyboards become common in laptops and why?

A: They became widespread in laptops from the 1990s onward because they saved space, weight, and cost while keeping noise low.

Q: How do membrane keyboards compare to mechanical ones?

A: Membranes are quieter, cheaper, and slimmer; mechanicals provide stronger tactile feedback and often greater longevity.

Q: Can membrane keyboards be repaired or recycled?

A: Basic fixes (cleaning, drying) can restore function, but full repairs are often impractical; recycling options are improving as manufacturers adopt recyclable films and safer inks.